3D Printings Services

- Instant quotes for rapid prototyping

- SLA, SLS and FDM services

- DFM feedback and analysis

3D Printing Services

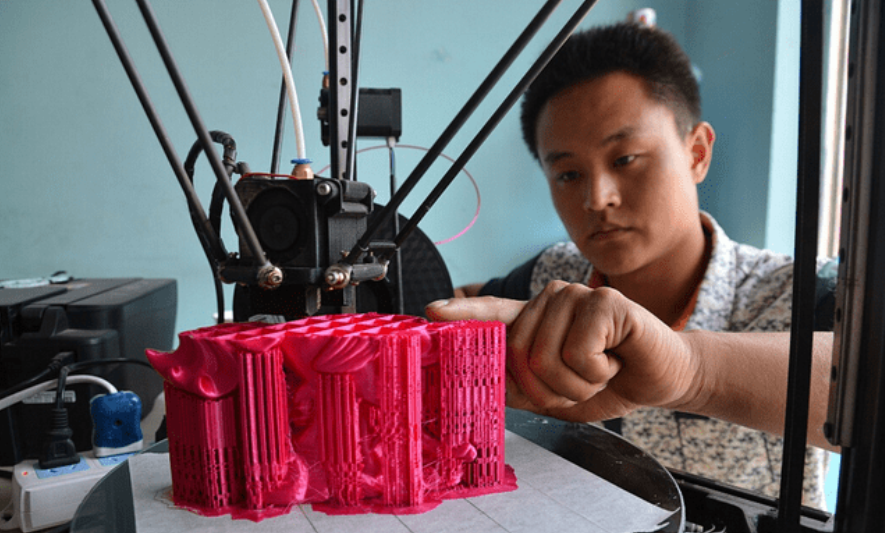

FDM

Fused Deposition

Modelling

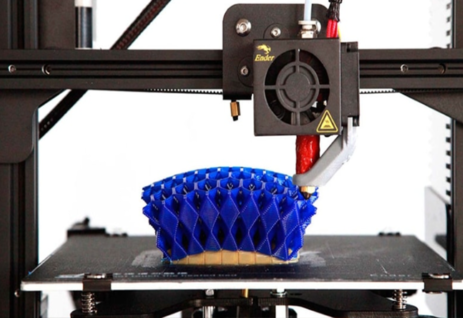

SLA

Stereolithography

SLS

Selective Laser

Sintering

High Quality 3D Printing Prototypes and Production Parts

At SMT, they have advanced 3D printing machines that enable you to quickly produce parts for your projects – whether you require a small batch or mass production. With CAD software, designing a part is easy, and SMT’s printers make it possible to print the part in a few hours, without any elaborate setup process. 3D printing is very versatile and can be used to create fully-functional prototypes with moving parts or assembly parts. Additionally, the fact that no tooling is required for 3D printed parts means that there’s a lower risk involved in producing a part. In case an error is detected after printing, it’s easy to digitally make adjustments without the need to replace costly tooling.

SMT Advantages

Reduce Cost

Unlike subtractive processes like machining, 3D printing create less waste material during the production. Also, it requires no toolings and becomes one of the most affordable and rapid manufacturing processes for one piece of prototype to small batches.

Wide Materials Selection

We use a range of commercial-grade thermoset resins, and thermo-plastic to 3D print parts that are suitable for various applications and industries. As per your requests, we offer a variety of post process options such as, secondary machining, plating, painting, and dyeing to further enhance mechanical properties and cosmetics.

Rapid Quotes & Manufacturability Feedback

Our 3D Printing Services

FDM Capabilities

Materials ABS, PC, PETG, PLA

Bed Sizes: PETG,PLA: 1250mmx 1800mmx 1000mm

ALL: 500mm x 500mm x 500mm

Minimum Dimensional Requirement 1mm

Tolerance :+0.2 to +0.25mm

Lead Time.2 to 3 days

SLA Capabilities

Materials: Standard, Tough (ABS like),

Clear, Durable (PP like), Castable,

High Temp Resin, Pro-Black

Bed Sizes: 380mmx 380mm x 250mm

600mm x 600mm x 550mm

750mm x 650mm x 500mm

Minimum Dimensional Requirement: 0.85mm

Tolerance: ±0.15 to +0.20mm

Lead Time: 2 to 3 days

SLS Capabilities

Materials: Nylon PA12, G F Nylon

Bed Sizes: 320mm x 320mm x 640mm

381mm x 330mm x 460mm

Minimum Dimensional Requirement: 0.85mm

Tolerance:±0.15 to +0.20mm

Lead Time: 3 to 4 days

Materials for 3D Printing

ABS

Provides favourable mechanical properties such as impact resistance, toughness, and rigidity.

Process: FDM

Tolerance: ±0.2 to +0.25mm

ABS -Like

ABS-like is our closest representation of injection molded ABS in a 3D printed material.

It has the same high resolution appearance as VeroWVhite, but the material is much stronger and more durable.

Process: SLA

Tolerance: +0.15 to ±0.20mm

Nylon - Like

Nylon PA12: Robust thermoplastic with all-around excellent physical properties. It is suitable for prototyping and even for end-product use.

G F Nylon: Glass-filled Nylon has a higher

stiffness and thermal stability

Process: SLS

Tolerance: +0.15 to +0.20mm

PETG

High impact resistance, warpage resistance, low shrinkage rate and high head deflection temperature. PETG (Polyethyene terephthalate glycol) is a useful 3D printing material for mechanical early-stage prototypes.

It's a great option that merges the cost-effectiveness of PLA and functionality of ABS

Process: FDM

Tolerance: +0.2 to +0.25mm

PLA

Can be printed at low temperature, biodegradable and cost-effective. PLA is a great 3D printing material for eariy stage prototyping on simple geometry parts, made out of bio-degradable comn starch.

Process: FDM

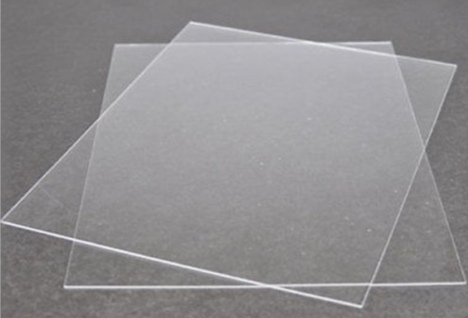

Polycarbonate (PC)

PC has high toughness, great impact strength and machinability.PC can also be optically transparent. Heat resistant upto 135°C, highly durable, shatter resistant transparent

Process: FDM

Manufacturing is Easy with SMT Machining

We promise to offer High Cost-Performance Parts at Low Cost

Fair Pricing

Get in-depth insights to improve your design for manufacturing. Choose the right material and get fair pricing for fabrication.

Build Fast. Learn Fast.

Building things is hard, it doesn't need to be slow. We speed up the process using our curated prototyping resource pool.

Quality Assurance

lf a part is not made to spec, we'll make it right. From factory audits to part inspections, we follow strict processes to meet the highest quality standards.

Massive Manufacturing Capacity

From your desktop, instantly access the production capacity of SMT Group and our material vendors with wide-ranging capabilities and certifcations across China.

3

Manufacturing Plants

25+

Years of Professionalism

100+

CNC Systems and

Casting Machines

500+

Int'l Customers served

4.5m+

Parts & Prototypes produced

Our Other Manufacturing Services

Sheet Metal Fabrication

Laser Cutting, Blending,

Welding & Assembly

CNC Machining

Milling (3, 4 & 5-axis),

Turning & Post-Treatment

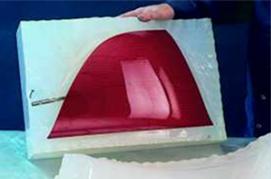

Vacuum Casting

Low Volume, High Quality,

Short Turnaround Time

Volume Production

Die Casting, Stamping &

Injection Molding