Manufacturing on Demand for

Medical Industry

- Suitable for scaling from 1-10000 parts

- Offers a wide variety of material

- Provides high precision tolerances

Custom Manufacturing Services for Medical Industry

At SMT Machining, we collaborate with top medical device manufacturers, wearable technology startups, suppliers, and research facilities to speed up the development of prototypes and expand their manufacturing capacity. Our clients in the medical equipment and product field rely on our efficient production capabilities, including industrial-grade 3D printing, cutting-edge CNC machining techniques, and advanced medical injection molding. We can quickly create prototypes, test products, design custom tools, and manufacture products with precision to meet the needs of our customers.

SMT Advantages

High Precision Manufacturing

With our advanced, in-house CNC milling centers, we can deliver tolerances as tight as 5 microns.

Rapid Quotes & Manufacturability Feedback

Streamline your workflow with our pre-sales supporting team with experienced sales engineers. Simply send your CAD model for quick pricing and DFM feedback within 24 hours.

Why SMT for Medical Industry ?

We promise to offer High Cost-Performance Parts at Low Cost

Fair Pricing

Get in-depth insights to improve your design for manufacturing. Choose the right material and get fair pricing for fabrication.

Build Fast. Learn Fast.

Building things is hard, it doesn't need to be slow. We speed up the process using our curated prototyping resource pool.

Quality Assurance

lf a part is not made to spec, we'll make it right. From factory audits to part inspections, we follow strict processes to meet the highest quality standards.

Massive Manufacturing Capacity

From your desktop, instantly access the production capacity of SMT Group and our material vendors with wide-ranging capabilities and certifcations across China.

3

Manufacturing Plants

25+

Years of Professionalism

100+

CNC Systems and

Casting Machines

500+

Int'l Customers served

4.5m+

Parts & Prototypes produced

CNC Machining for Medical Industry

CNC machining is a vitally important manufacturing process for the medical industry. From surgical tools to bedside monitoring devices to hip implants, machined parts can be found throughout the world of healthcare. Common materials for machined implants : Titanium alloys such as Ti6Al4V, Cobalt-chrome alloys, Stainless steels, Polyether ether ketone (PEEK), surgical steel (AISI 316L)

Common Applications

- Hip implants, Spine implants, Knee implants

- Handles, Cutters, Saws

- Forceps, Holders, Clamps, Spacers

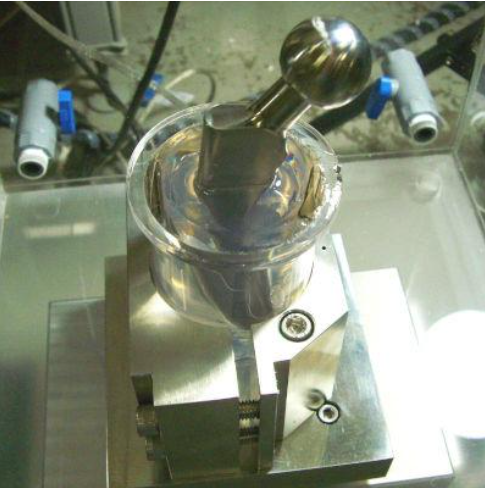

Injection Molding for Medical Industry

The medical grade plastic materials we use for medical injection molding have high molecular weight and feature chemical and heat resistant properties. Each type of thermoplastic used for medical molding also features different advantages and qualities you will want to review before selecting a material for your injection molding application.

Common Applications:

- Implantable components

- Beakers, test tubes and other containers

- Housings and casings for medical and laboratory equipment

- Drug delivery equipment and components

Metal Fabrication for Medical Industry

Medical device enclosure is a device utilized for putting different medical instruments, for example medical thermometers, surgical products, blood/sugar meters, operation theatre equipment and numerous different devices securely. We fabricate and supply these medical device enclosures in diverse grades and particulars dependent upon the necessities of our clients

Materials Available:

- Stainless Steel

- Mild Steel

- Aluminium