Manufacturing on Demand for

Aerospace & Defense

- Offers a wide variety of material

- Military Grade Surface Treatments

- Provides high precision tolerances

Custom Manufacturing Services for A & D Industries

The aerospace and defense industry is recognized for its production of sophisticated and innovative products like jet engines, aircrafts, rockets, satellites, and drones, which have to be developed quickly and within strict regulations. Due to this, precise parts and components become crucial in the production cycle.

SMT has implemented digital manufacturing techniques to enhance the production of high precision and multi-purpose parts. In addition, the utilization of diverse manufacturing materials and practices can accelerate the manufacturing process while also enhancing the value of the designs. We specialize in using military grade surface treatments and coatings such as Chromate Conversion Coating (Alodine) that exhibit extreme heat tolerance and exceptional anti-wear capabilities. Lastly, SMT has optimized quality and adherence measures to ensure consistency and compliance with industry standards.

SMT Advantages

High Precision Manufacturing

With our advanced, in-house CNC milling centers, we can deliver tolerances as tight as 5 microns.

Expertise in Super Grade Anodizing and Coating

At SMT, we pride ourselves on our ability to deliver special surface treatments that meet our customers’ unique specifications. Our expertise includes the application of Type III Anodizing (Hardcoat) in accordance with Mil-A-8625 and Chromate Conversion Coating using Henkel’s Alodine per MIL-DTL-5541, ensuring a high standard of quality.

Rapid Quotes & Manufacturability Feedback

Streamline your workflow with our pre-sales supporting team with experienced sales engineers. Simply send your CAD model for quick pricing and DFM feedback within 24 hours.

Why SMT Machining for A & D ?

We promise to offer High Cost-Performance Parts at Low Cost

Fair Pricing

Get in-depth insights to improve your design for manufacturing. Choose the right material and get fair pricing for fabrication.

Build Fast. Learn Fast.

Building things is hard, it doesn't need to be slow. We speed up the process using our curated prototyping resource pool.

Quality Assurance

lf a part is not made to spec, we'll make it right. From factory audits to part inspections, we follow strict processes to meet the highest quality standards.

Massive Manufacturing Capacity

From your desktop, instantly access the production capacity of SMT Group and our material vendors with wide-ranging capabilities and certifcations across China.

3

Manufacturing Plants

25+

Years of Professionalism

100+

CNC Systems and

Casting Machines

500+

Int'l Customers served

4.5m+

Parts & Prototypes produced

A & D Parts Manufactured at SMT

SMT recognizes the significance of promptness. Our experience collaborating with firms in the aerospace and defense sector has enabled us to hasten the advancement of various metal and plastic aerospace parts and items, such as

- housings & lids for electronic module

- heat exchangers

- manifolds

- turbo pumps

- liquid and gas flow components

- fuel nozzles

- conformal cooling channels

- turbine blades

- shafts

- valve components

- structural components and etc

CNC Machining for A & D

CNC Machining is quick and efficient to produce highly precise components for Aerospace & Denfense Applications such as Gears, Transmission Components, Shafts and Adaptors, Custom Enclosures, Mounts and other special mechanisms like Housing & Lids for Electronic Module.

Materials Available

- Aluminium 2, 6 and 7 series

- Titanium and Stainless Steel Alloys

- Copper Alloys like Brass and Bronze

- Nylons, natural and glass filled

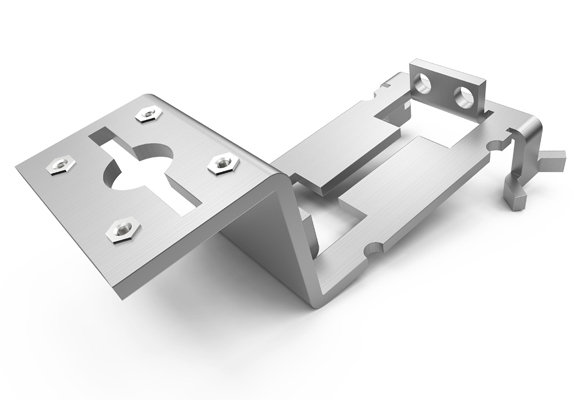

Sheet Metal Fabrication for A & D

Precision laser cutting followed by CNC bending and welding allows you to produce custom brackets, clamps, jigs and heavy duty enclosures in steel and aluminium.

Materials Available:

- Stainless Steel

- Mild Steel

- Aluminium