Sheet Metal

Fabrication

- Suitable for scaling from 1-10000 parts

- Offers a wide variety of material

- Provides high precision tolerances

Sheet Metal Operations

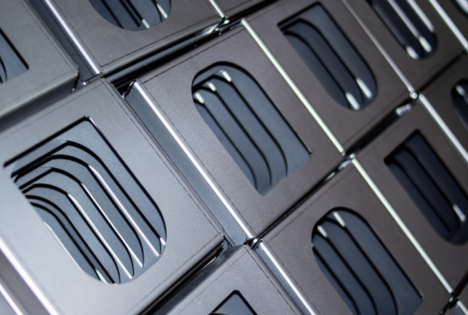

CNC Bending

CNC bending uses dies to producea U-shape,V-shape. or channel shape as per the design.

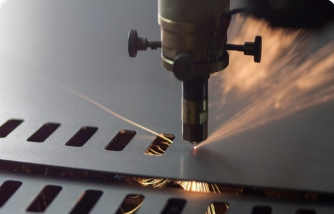

Cutting Services

Laser and Waterjet cutting services for a wide variety of materials from 0.2mm.

Welding & Assembly

Fabrication of sheet metal components for panels, brackets and enclosures.

Surface Finishing

Powder coating, anodising. sand blasting. bead blasting. Teflon coating. PVD coating

Custom Sheet Metal Fabrication Service

Unlike traditional sheet metal factories, SMT engages its own in-house and associated partners’ facilities to ensure on-time shipment for every order, whether you need a single or upto 10000 parts. You also have access to our team of knowledgeable engineers to optimize part designs and user-friendly online resources. Trim your production time and launch products faster with one local sheet metal supplier from prototypes to assemblies to finishing options.

SMT Advantages

Quality Assurance

We guarantee your custom sheet metal parts will be built to your specifications. We are constantly monitoring our finished products to ensure the highest quality parts at low prices and competitive lead times.

Rapid Quotes & Manufacturability Feedback

Streamline your workflow with our pre-sales supporting team with experienced sales engineers. Simply send your CAD model for quick pricing and DfM feedback within 24 hours.

Speedy Delivery

SMT has a distributed network of sheet metal partners and promising speedy delivery for every order.

Materials for Sheet Metal Fabrication

Aluminium

Aluminium is remarkable for its excellent strength-to-weight ratio and low cost. This material can be used for fabricating quick enclosures, brackets and casings.

Thickness: 0.5 to 8 mm

Finishing Options: Anodising, Black

Oxide Coating

Lead Time: 3 to 4 days

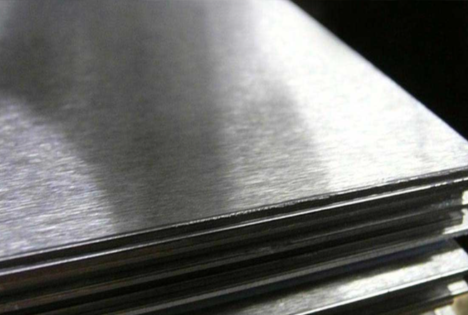

Stainless Steel

Stainless Steel being highly resistant to dust and corrosion make up for ideal enclosures, brackets and complex components. High versatility and robust designs help quick and easy manufacturing.

Thickness: 0.2 to 8 mm

Finishing Options: Natural

Lead Time: 3 to 4 days

Mild steel

Highly malleable and corrosion resistant material allowing excellent design features and manufacturability at a cheaper rate as compared to other materials.

Thickness: 0.5 to 8 mm

Finishing Options: Powder Coating, Spray

Painting, Zinc Coating

Lead Time: 3 to 4 days

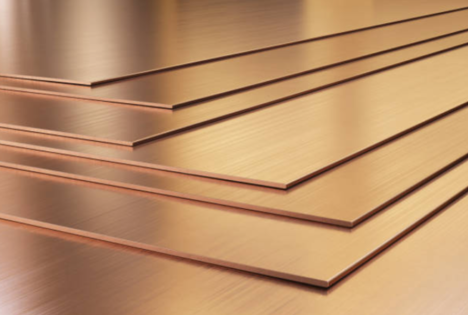

Copper

Copper offers great conductive and strength which finds major applications in shine and busbar production.

Thickness: 0.2 to 8 mm

Finishing Options: Nickel Pilating

Lead Time: 3 to 4 days

Nickel

Nickel is considered to be the most versatile and corrosion resistant material mostly used for chemical applications.

Thickness:0.2 to 8 mm

Finishing Options: Any RAL and Pantone Shade

Lead Time: 3 to 4 days

Cutting Options

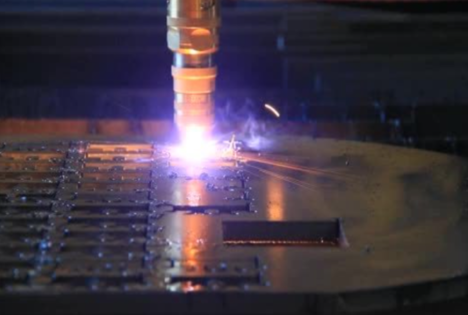

Laser Cutting

High power laser beam is used to heat the workpiece to the required temperature so as melt and vapourise the material, cutting as per the design.

Bed Size:3000mmx 1500mm

Thickness of Material upto:

SS and MS:12 mm

Aluminium:10mm

Brass and Copper:6 mm

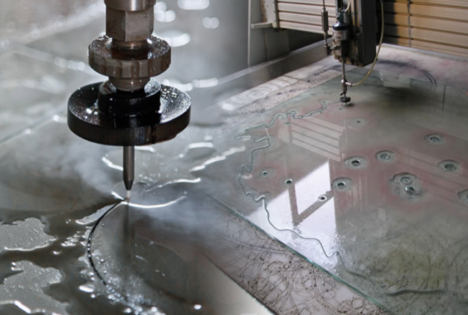

Waterjet Cutting

n waterjet cutting, workpieces are separated from each other by a high-pressure water jet using either specially treated water or an abrasive agent.

Bed Size:3000mm x2000mm

Thickness of Material upto:

SS and MS: 150 mm

Aluminium: 180 mm

Wood / Plastics: 120 mm

Precision Laser Cutting

Great Light also provides precision laser cutting services for various applications such as shins and busbars.Operations can be done on materials of minimum thickness 0.2mm.

Material upto: Nickel, Copper, SS

Manufacturing is Easy with SMT Machining

We promise to offer High Cost-Performance Parts at Low Cost

Fair Pricing

Get in-depth insights to improve your design for manufacturing. Choose the right material and get fair pricing for fabrication.

Build Fast. Learn Fast.

Building things is hard, it doesn't need to be slow. We speed up the process using our curated prototyping resource pool.

Quality Assurance

lf a part is not made to spec, we'll make it right. From factory audits to part inspections, we follow strict processes to meet the highest quality standards.

Massive Manufacturing Capacity

From your desktop, instantly access the production capacity of SMT Group and our material vendors with wide-ranging capabilities and certifcations across China.

3

Manufacturing Plants

25+

Years of Professionalism

100+

CNC Systems and

Casting Machines

500+

Int'l Customers served

4.5m+

Parts & Prototypes produced

Our Other Manufacturing Services

CNC Machining

Milling (3, 4 & 5-axis),

Turning & Post-Treatment

3D Printing

Rapid Prototyping in

Plastics, Elastomers & Metals

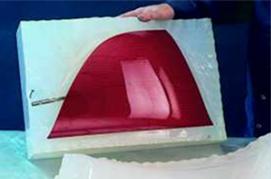

Vacuum Casting

Low Volume, High Quality,

Short Turnaround Time

Volume Production

Die Casting, Stamping &

Injection Molding