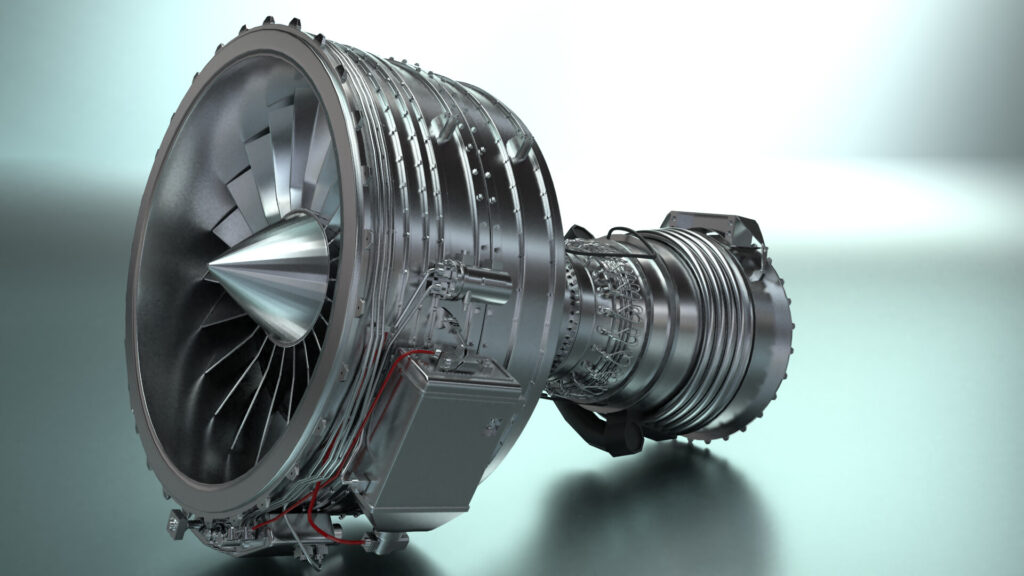

Manufacturing on Demand for

Turbine Blades / Fans

-

Turbine blades, fans and impellers

for car turbo and compressor - Provides high precision tolerances

Custom Manufacturing Services for Turbine Blades

To machine intricate and vital parts like turbine blades, it is essential to have a comprehensive machining plan that emphasizes ongoing enhancements to boost efficiency and streamline subsequent procedures. Tackling the obstacles involved demands innovative techniques and a skilled team with expertise in different machining operational capacities, notably when dealing with revolving blades.

SMT Advantages

High Precision Manufacturing

With our advanced, in-house CNC milling centers, we can deliver tolerances as tight as 5 microns.

Rapid Quotes & Manufacturability Feedback

Streamline your workflow with our pre-sales supporting team with experienced sales engineers. Simply send your CAD model for quick pricing and DFM feedback within 24 hours.

Why SMT for 3C Product Parts ?

We promise to offer High Cost-Performance Parts at Low Cost

Fair Pricing

Get in-depth insights to improve your design for manufacturing. Choose the right material and get fair pricing for fabrication.

Build Fast. Learn Fast.

Building things is hard, it doesn't need to be slow. We speed up the process using our curated prototyping resource pool.

Quality Assurance

lf a part is not made to spec, we'll make it right. From factory audits to part inspections, we follow strict processes to meet the highest quality standards.

Massive Manufacturing Capacity

From your desktop, instantly access the production capacity of SMT Group and our material vendors with wide-ranging capabilities and certifcations across China.

3

Manufacturing Plants

25+

Years of Professionalism

100+

CNC Systems and

Casting Machines

500+

Int'l Customers served

4.5m+

Parts & Prototypes produced

SMT Makes Machined Parts for Turbine System

Manufacturing Service for Turbine Blades

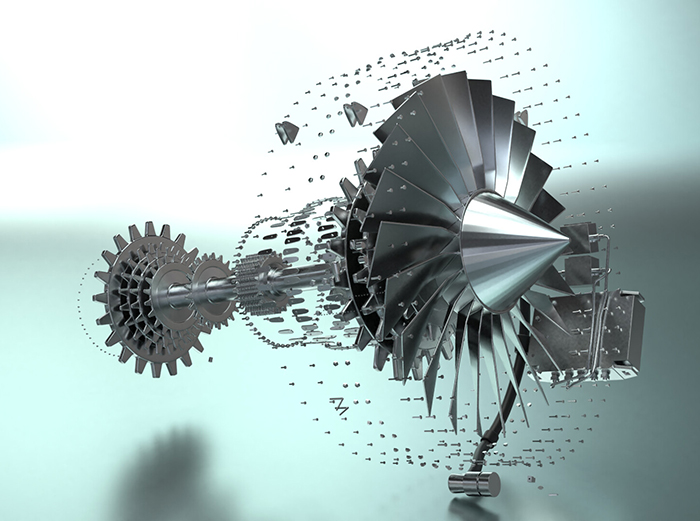

Roughing the blade rhombus and aerofoil, especially of medium-sized blades, from blanks, to achieve the basic blade form is often at the center of attention as it represents the bulk of machining. Many of these are made in martensitic stainless steel but blades are also made in Duplex, HRSA and Titanium.

These operations have seen a number of different solutions through the years and with the advancement of tools, design and manufacturing technologies. The best balance between feed, depth of cut, RPM and selection of right tools as well as the cutting forces generated should be established to achieve optimized performance, safety and results.